Related Products

If you konw more about other cnc woodlathes please check here

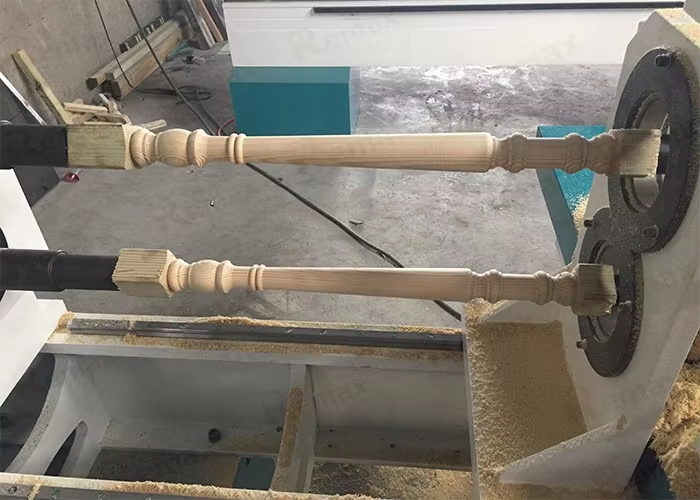

The ST-1516 dual double-axis CNC lathe wood stands out as a top-tier machine, blending precision, efficiency, and versatility. Designed for a wide range of woodworking applications, this advanced lathe is perfect for both novice and professional woodworkers. With robust features and state-of-the-art technology, it ensures high-quality production of various wooden crafts and components.

The ST-1516 is equipped with a heavy cast iron lathe bed, providing exceptional stability and minimizing vibrations during high-speed spindle rotations. This feature is particularly beneficial when processing large workpieces, ensuring precise and smooth operations. The main spindle speed can be adjusted via a frequency converter for optimal performance.

Incorporating Taiwan PMI helical guides and German ball screws, the ST-1516 guarantees high precision and durability. These components ensure smooth and accurate movements, contributing to the overall reliability of the machine.

The machine comes with an intuitive CNC panel control system and supports AutoCAD software. It is simple to learn and operate, even for beginners. The system supports various G-code drawings, including DXF, 3DS, STL, PSD, AI, DWG, BMP, STP, IGS, and more.

Equipped with a 5.5KW big stepper motor and YAKO 2D811 drivers, the lathe delivers robust performance for various woodworking tasks.

Featuring two horizontal spindles, this innovative design supports heavy-duty operations with fast speed and high precision.

Model: | ST-1516(1500*160mm) 2 axis with four cutter 3.5 kw spindle for 3d carving for optional |

Structure: | Cast iron |

Spindle shaft: | Sturdy spindle, NSK deep groove ball bearing, P5 grade. |

Drive system: | – Three phse current of 380V, 50HZ. 4 Kw. , 1 set – Stepper motor: 450B 2 sets – Stepper driver: YKAO2811MA 2 sets – Servo motor is optional 5.5kw 220v/3ph/220v/1ph for optional |

Inverter: | Best inverter 5.5 kw (Fuling brand is optional) |

Guide rail: | Taiwan HIWIN/PMI linear square guide rail. |

Spindle speed: | 3000 r/min |

Material size: | 300*1500 mm (length: 2000mm, 2500mm, 3000mm are optional) |

Center Sleeve ID: | 1.414 times the side length of material (no need sleeve if material diameter is more than 60mm) |

Weight – bearing: | 500 kg |

Engraving speed: | 4 m/min |

Max. feed | 15 mm/r |

Max. feed rate: | 700 mm /min |

Min. setting unit: | 0.1 mm |

Pivoting device: | Pneumatic air connection within 6-8 bar. |

Tailstock: | Precisely and easily movable, with quick clamping with pneumatic |

Electric system: | Air break switch protection |

Dimensions(L*W*H):Machine (without operation box) | 3100 *1280*1780 mm |

Packing dimensions:Machine (with operation box) | 3200*1380*1980 mm |

Weight: | 1700 kg |

Software | AUTOCAD (DXF format ) |

Control system: | LCD control with screen show |

Planner | for optional |

The ST-1516 CNC wood lathe features a heavy-duty cast iron lathe bed, PLC computer controller ,Taiwan PMI helical guides, German ball screws, single and biaxial spindles, domestic famous brand stepper motors, spindle speed display on the cabinet panel, and one-time tool setting.

The dual double-axis design allows the lathe to produce two pieces simultaneously, effectively doubling the output compared to single-axis lathes. This setup enhances productivity and efficiency, making it ideal for large-scale production.

The heavy cast iron lathe bed provides exceptional stability and minimizes vibrations during high-speed spindle rotations. This ensures precise and smooth operations, especially when processing large workpieces.

Taiwan PMI helical guides and German ball screws ensure smooth and accurate movements, contributing to the high precision and durability of the machine. These components are crucial for maintaining the lathe’s reliability and performance

Yes, the biaxial spindle design allows the lathe to produce two pieces simultaneously, significantly increasing the output and efficiency.

The spindle speed is adjustable via a frequency converter, and the speed data is displayed on the cabinet panel for real-time monitoring and adjustments.

The one-time tool setting feature simplifies the setup process and saves valuable time. This enhances productivity and ensures consistent results for each workpiece.

The ST-1516 is ideal for creating various cylindrical and bowl-shaped wooden crafts, including staircase columns, Roman columns, general columns, table and chair legs, washstands, wooden vases, wooden tables, baseball bats, car wooden furniture components, and children’s bed columns.

Yes, the machine is equipped with an intuitive CNC panel control system and supports AutoCAD software, making it simple to learn and operate even for beginners. It supports various G-code drawings, facilitating easy programming and customization.

Yes, the machine size can be customized according to specific customer needs, offering flexibility and tailored solutions to meet various production requirements.

The machine supports AutoCAD software and various G-code drawings, including DXF, 3DS, STL, PSD, AI, DWG, BMP, STP, IGS, and more. This compatibility facilitates easy design creation and import for CNC machining.

The ST-1516 is equipped with a 5.5KW big stepper motor and YAKO 2D811 drivers, ensuring robust performance for various woodworking tasks.

Jinan Suntec CNC Machinery Co., Ltd. is a leading manufacturer and exporter dedicated to the design, development, and production of high-quality CNC wood lathes, CNC routers, 5-axis CNC routers, and other advanced woodworking machinery.

Company Philosophy

At Jinan Suntec CNC Machinery Co., Ltd., our mission is to advance the CNC wood lathe industry by providing exceptional products and services, driven by innovation and a customer-first approach.

If you konw more about other cnc woodlathes please check here